SoftLux microcement | Floor kit

| Projects: Floor |

SoftLux floor microcement

Each kit contains the amount needed to apply two coats of microcement, two coats of sealer and two coats of varnish.

AVAILABLE COLORS

White

Grey

Rock

Ash

Beige

Ocean

Ocean

Greige

Pearl

Hemp

Slate

Tuscany

Tuscany Ochre

Ochre

Almond

Sage

Sage Brun

BrunFLOOR MICROCEMENT

SoftLux

A kit to customize your floor

Physical properties

Specifications

- VOC 0 g/L

- pH 11

- Density 1.28 kg /L

Resistance

- Chemical resistance: excellent

- Abrasion resistance: ASTM D4060 (concrete wheel H22, 1000 cycles) – 0.80 g (loss)

- Durability: very high

Composition

Main component: Portland cement

Conservation

Powder shelf life: 2 years (when the bucket is properly sealed and stored in a dry place)

Recommended substrates

The substrate must be sound, dry, waterproof, and stable

- Poured concrete

- Concrete screed

- Ceramic

See the surface preparation instructions..

Flexibility

On HDF 3.2 mm (1/8''), minimum cylinder diameter D > 305 mm (12'')

Strength after 30 days: > 25 MPa

Technical data

Coverage

Available formats

- 4,5 kg : covers approx. 35 to 45 sq. ft.

- 8 kg : covers approx. 50 to 65 sq. ft.

- 12 kg : covers approx. 75 to 90 sq. ft.

- 18 kg : covers approx. 110 to 130 sq. ft.

Application tools & cleaning

- Trowel or taping knife

- Clean tools with water

Usage

- Drying time (may vary depending on conditions) :

- To the touch: 1 to 3 hours

- Recoating:

- 4 hours

- Light foot traffic: 12 hours

- Storage conditions: between 10°C and 30°C (50°F and 85°F); avoid humidity

- Mix ratio: 1 kg of microcement to 200 ml of additive

- Working time (pot life): approximately 30 minutes

Kit contents

Each kit includes :

- Microcement mortar

- Additive

- Protective sealer

- Protective varnish

Includes the necessary amount to apply two layers of microcement, two layers of sealer, and two layers of varnish.

EXCELLENT ADHERENCE

VERY RESISTANT, DURABLE

Thickness | Application | Resistance | Resistance | Maintenance | Advanced protection | Color Variation |

Two 1 mm layers

| Applied with a trowel

| Water resistant

| fire-resistant

|

Easy to clean with mild, eco-friendly products

| Antibacterial

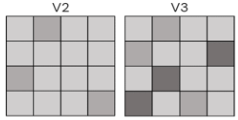

| V2 - V3

|

Indoor application

application for floors

Poured concrete floor

Stairs

Tiled surfaces to cover

FLOOR MICORCEMENT APPLICATION STEPS

Step 1

Prepare the surface

(it must be smooth, sound, and waterproof)

Step 2

Apply two layers of microcement (1 mm each)

Drying time between layers :

Minimum 6 hours.

Step 3

Sand the surface with 80 to 100 grit, then vacuum.

Sanding is only intended to lightly smooth the surface.

Step 4

Apply two coats of penetrating sealer

Drying time :

- Minimum 6 hours between coats

- 24 hours after the final coat

Step 5

Apply two coats of varnish

Apply using a lint-free velvet roller

The 2 coats must be espaced 24 hours apart.